Have you ever been asked “ Excuse me sir, have you any idea how fast you were going?”.

The question that every motorist dreads being asked by a police officer at the side of the road. If you were staring straight ahead, not looking at the dashboard, you might have no accurate answer to say. If you were looking at the speedometer, on the other hand, you’ll know the precise answer. Have you ever think about how a speedometer actually work?

What do you think of a speedometer work?

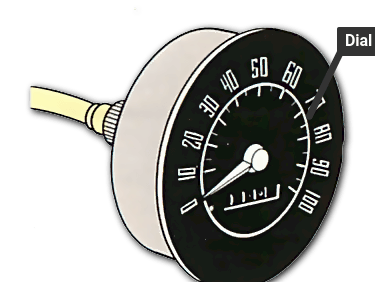

Of all the instruments you can find on a modern car dashboard, only one is a legal requirement – that is speedometer! In common with other developments in car technology, the trend is now towards using electronics in speedometer, usually with a needle and calibrated dual to show the speed. The design of this type of speedometer has hardly changed in the last 50 years.

Operations

Mechanical speedometers measure the speed of a car being linked mechanically with the gearbox output shaft. Since this shaft lies “downstream” of the gear box, the speed with which it rotated us independent of gear changes and so gives a true measure of the road speed.

Inside the gearbox, the output shaft contains a gear wheel which rotates with the shaft. The speedo cable consists of an inner cable running inside a protective outer sheath. The ends of the speedometer inner cable are squared off, and fit into squared holes in the drive pinion at the gearbox and the drive in the back of the speedometer. As the pinion rotates, driven by the gearbox output shaft, it caused the inner cable to rotate with it.

The other end of the cable fits to a drive shaft leading into the speedometer. On the end of this shaft is a magnet. Positioned close to the magnet is a cup-shaped metal drum that is attached to the needle giving the reading on the dial. A small coiled hair spring holds the needle at zero.

The drum is attracted by the magnet so, as the magnet turns, the drum turns too. The faster the car is traveling, the greater the pull of the magnet on the metal drum and the further the needle moves round the dial. But the restraining force of the hair spring also increases as the needle moves round the dual. At a certain point the forces of the spring and the magnet balance out and the needle steadies to give a reading.

Mechanical Speedometers

As you press your gas pedal, the wheels of your car spin faster or slower according to how much gas is being supplied to the engine cylinders. When you want to check how fast you are going, you check your speedometer, which tells you the speed in kilometers and or miles per hour.

The speedometer gets it’s speed reading by gauging how quickly the wheels are spinning it then uses electromagnetism to convert the spinning wheel energy into a smooth drifting motion in the gauge. The cable will measure the rotation and feed back to the speedometer turning a magnet.

The magnet is able to rotate freely within the speed cup which also rotates. The speed cup is connected to a wire coil and to the gauge itself and dictates the speed reading.

The Specifies If You Care

So the speedometer cable attaches to the drive train. As it spins freely with the transmission, it turns a magnet at the same speed. The spinning magnet is located within the speed cup and within it creates a magnetic field that varies with the speed of the vehicle and with the cable turning.

What happens from here is that the speed cup generates electricity. Electricity that really has no where to go. This is where the mechanical speedometer gets its nickname Eddy Current Speedometer. These rotating electrical currents will cause the speed cup to rotate, trying to match the speed of the rotating magnet.

The fine coil prevents the speed cup from fully rotating which causes it to pull the pointer up the speedometer display. The faster the car goes, the faster this entire reaction happens beginning with the spinning cable.